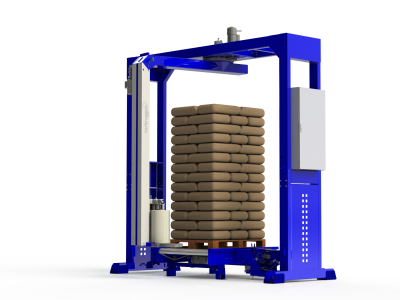

Pallet wrapping machine repair and its impact on productivity

How to Optimize Effectiveness With a Pallet wrapping Device: Common Repair Tips

Making best use of performance with a pallet wrapping equipment needs a strategic approach to repair and maintenance. Routine checks are vital to assure all components work efficiently. Usual concerns such as irregular film tension and jamming can interrupt operations. Attending to these issues quickly can improve performance. Understanding the nuances of readjusting tension and preserving sanitation is just as important. What particular actions can be taken to guarantee peak efficiency?

Regular Maintenance Checks

Normal upkeep checks are necessary for making certain the ideal performance of a pallet wrapping maker. These checks not only boost the durability of the equipment yet also improve functional effectiveness. Regular assessments must include analyzing the maker's electrical parts, ensuring that all links are secure and complimentary from deterioration. The film dispensing system should be looked for appropriate placement and tension to prevent operational disturbances. In addition, oiling relocating components minimizes friction and wear, maintaining smooth performance. Operators should additionally examine the control panel for any type of abnormalities in readings or performance. Regular upkeep cultivates an aggressive approach to equipment treatment, eventually leading to minimized downtime and increased efficiency in the wrapping process. Complying with a scheduled upkeep strategy is important for ideal efficiency.

Troubleshooting Common Concerns

Replacing Damaged Components

Replacing damaged components is important for keeping the perfect efficiency of a pallet wrapping device. Regular examinations help identify parts that show signs of wear, such as the film carriage, rollers, or drive belts. These parts can degrade gradually, leading to inadequacies in wrapping operations. It is essential to pick premium parts that match the maker's requirements to assure compatibility and height efficiency when replacement is necessary. Technicians ought to follow the manufacturer's standards throughout the replacement process, as inappropriate setup can result in more issues. In addition, maintaining a supply of frequently required components can minimize downtime, enabling quicker repairs and maintaining efficiency degrees. Proactive upkeep and timely substitutes are key to expanding the maker's lifespan.

Changing Stress and film Setups

Maintaining excellent efficiency of a pallet wrapping equipment expands past changing worn-out components; it likewise includes adjust the stress and film setups. pallet wrapping machine repair. Appropriate tension is crucial for achieving ideal load security during transport. website If the stress is too limited, it might harm the load, while insufficient stress can bring about loose wrapping and potential shifting. Operators should regularly examine and change the stress settings according to the particular requirements of the load being wrapped

In addition, picking the right film kind and density is crucial for ensuring efficient wrapping. Thicker films offer boosted stamina yet might call for greater stress setups. On the other hand, thinner movies may be a lot more cost-efficient yet can endanger load safety otherwise appropriately tensioned. Routine changes will make the most of efficiency and reduce product waste.

Maintaining the Device Oiled and clean

Although frequently forgotten, maintaining the pallet wrapping equipment tidy and oiled is necessary for ensuring peak efficiency and durability. Regular cleaning helps avoid the buildup of dirt, debris, and deposit that can prevent mechanical features. It is advisable to clean down surfaces and get rid of any type of gathered products after each usage. Additionally, appropriate lubrication of moving parts decreases friction, decreases wear, and prolongs the life expectancy of the maker. Operators ought to seek advice from the manufacturer's standards for recommended lubes and maintenance timetables. Carrying out regular inspections to identify any indicators of corrosion or rust can likewise protect against even more considerable problems down the line. Sticking to these practices will certainly not only enhance performance however additionally promote secure operation of the pallet wrapping maker.

Often Asked Concerns

Just how Often Should I Change the Pallet wrapping film?

The regularity of changing pallet wrapping film depends upon use and wear. pallet wrapping machine repair. Commonly, it must be changed when indications of damage, splits, or excessive extending happen, making certain excellent efficiency and protection of the wrapped goods

Can I Utilize Various Kinds of Films With My Equipment?

Various kinds of films can typically be made use of with pallet wrapping machines, yet compatibility depends on the device's requirements. Users need to seek advice from the maker's standards to ensure peak performance and avoid prospective damage to the devices.

What Safety and security Precautions Should I Take While Operating the Machine?

When running a pallet wrapping maker, one must use proper personal safety equipment, assurance proper training, keep a clear work space, and frequently inspect the equipment for any type of possible threats to guarantee secure procedure.

How Do I Train New Worker to Make Use Of the Pallet wrapping Device?

To train new staff members on the pallet wrapping machine, one should provide complete presentations, thorough manuals, and hands-on practice. Routine evaluations and feedback will improve their skills and guarantee secure, efficient procedure.

What Are the Indications That My Maker Demands Expert Servicing?

Indications showing a demand for professional servicing consist of uncommon noises, inconsistent wrapping, regular mistake messages, and noticeable endure components. Prompt attention to these concerns can prevent additional damage and warranty optimal maker efficiency.

Regular upkeep checks are vital for guaranteeing the optimum performance of a pallet wrapping machine. Replacing damaged components is necessary for keeping the optimal efficiency of a pallet wrapping maker. Maintaining perfect performance of a pallet wrapping maker extends beyond replacing worn-out parts; it additionally entails tweak the tension and film settings. Usually neglected, keeping the pallet wrapping maker tidy and oiled is important for ensuring peak performance and long life. Different types of movies can generally be utilized with pallet wrapping devices, but compatibility depends on the device's specifications.